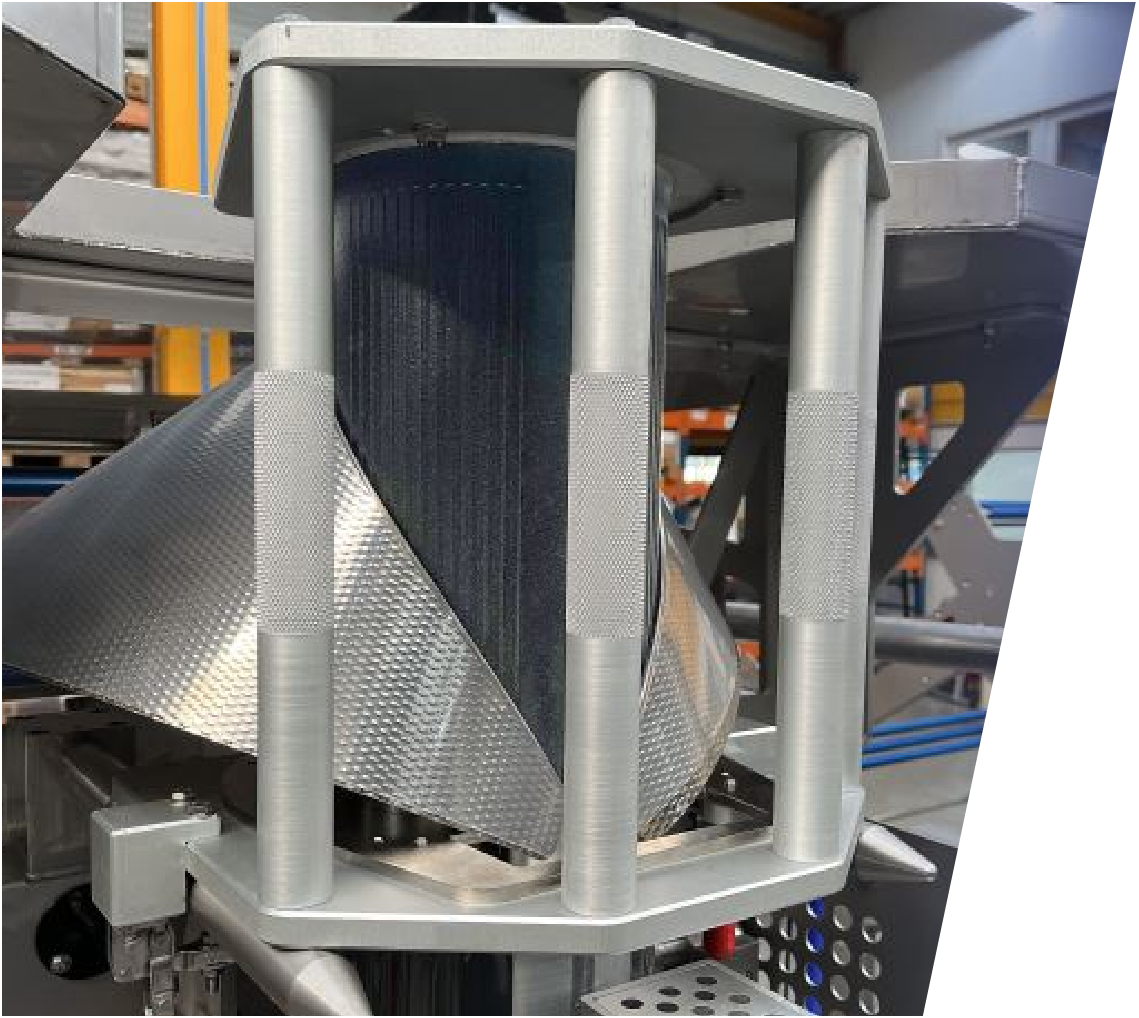

Filling tubes

Fully adaptable to our clients' requirements and processes

Throughput in humid and deeply chilled packaging environments is guaranteed with application of Breedewegh's non-stick coatings for filling tubes in VFFS machines.

The coatings can be applied to both aluminium and stainless steel filler pipes. Filler pipes already in use can also be treated with this, provided they have sufficient wall thickness.