Forming sets

Fully adaptable to our clients' requirements and processes

By constantly communicating and innovating based on customer requests, Breedewegh is constantly on top of the development of improvements and innovations. All in the interest of optimum returns from formate sets for vertical packaging machines.

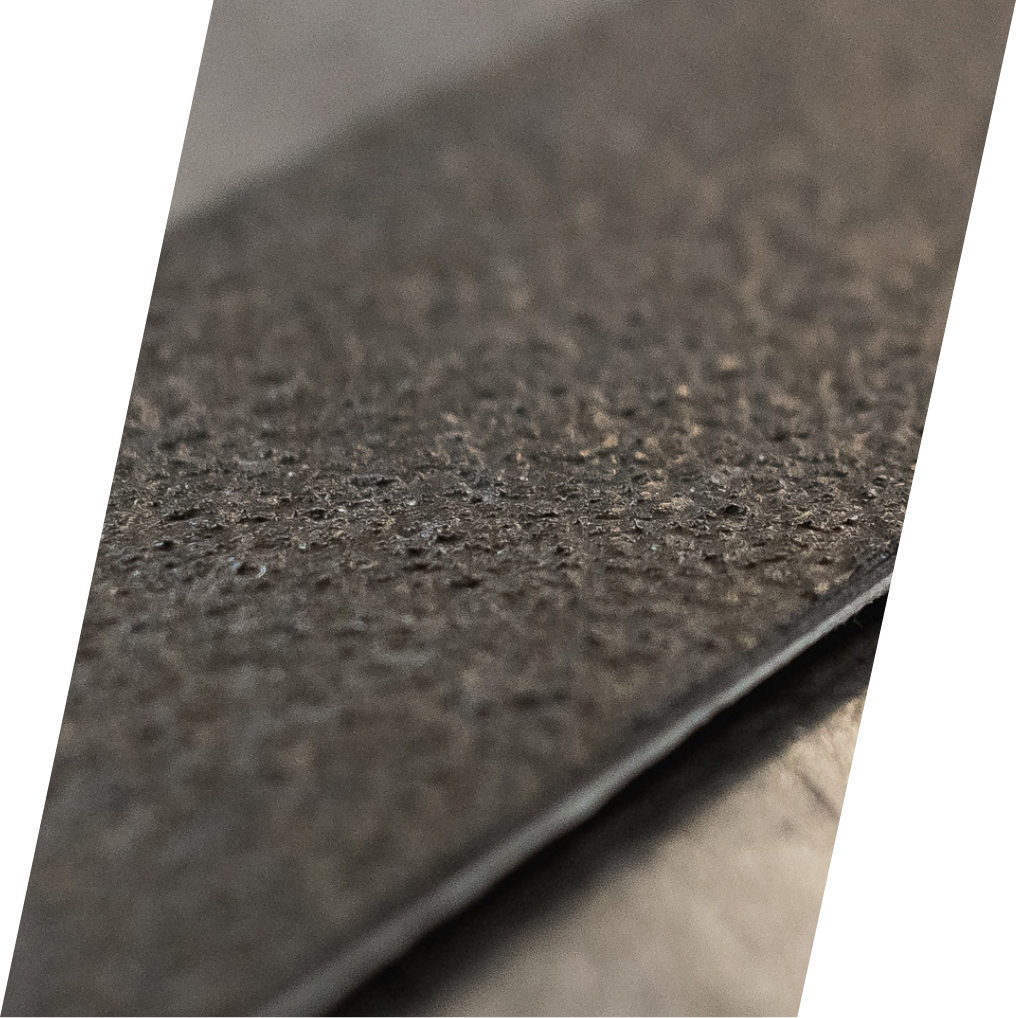

For example, we have format sets for packaging frozen foods, fresh vegetables, fruits, snacks, pet food, coffee, tea, sugars, powders pastes etc. They are suitable for all types of packaging and all types of packaging films.